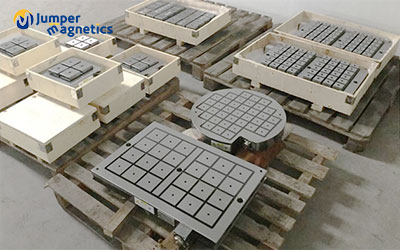

As the main featured products of Jumper Magnetics, our electro permanent magnetic chucks could be widely used for millding, grinding, turning and other applications, with the help of various kind of pole extensions. The performance features of your machine tools and machining centres will unfold their full potential because you’ll be able to machine all five sides of your workpiece during a single setup.

With our 10 years experience in magnetic workholding & lifting industries, Jumper Magnetic keep on optimizing our design of products.